- info@matltech.com

- Setsi sa Lefatše sa E2-1-1011, No. 177 Tianfu Avenue North, Chengdu 610041, China

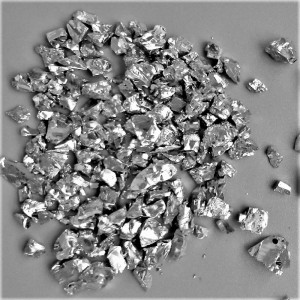

Motsoako oa Koporo oa Tellurium

Motsoako oa Koporo oa Tellurium, ka ho eketsa butle-butle liperesente tsa boima ba 99.99% pureurium ka har'a khoebo e qhibilihisitsoeng ea 9.99% ea koporo ea koporo seboping sa motlakase oa motlakase, 'me khabareng e' ngoe ea phosphorus e le deoxidant le li-microelements tse nyane li kenyelletsoa ka mokelikeli o qhibilihisitsoeng ho fumana tse lakatsehang motsoako oa koporo ea tellurium.

Ho ba phahameng tshebetso mahala itšeha, e leng nolofalletsa e phahameng haholo machining lebelo ho feta kamoo ho ka khonehang ka koporo e hloekileng, le sekala sa machinability e rated ka 90, bobeli sebetsa batang kapa chesang eaba ba etsa, le ka tshebetso e ntle selikalikoe-hanyetsa, haedrojene embrittlement, e phahameng motlakase oa motlakase (90% IACS) le mafura a ho futhumatsa, le ho thibela tšenyo, Tellurium Copper Alloy (C14500, CuTeP) e sebelisoa haholo bakeng sa ho tjheseletsa (ho itšeha ha hydrogen, ho itšeha ha acetylene le sesebelisoa sa ho tjheseletsa argon-arc), indasteri ea lik'hemik'hale le mechini ea diminerale joalo ka nozzle ea likoloi

Lihlahisoa tsohle li latela melao ea RoHS.

Lintlha

Litags

Ga tlhaloso Technical

|

Che. |

Ntho |

Standard ga tlhaloso |

|||

|

1 |

Kereiti |

Te |

Re |

P |

Cu |

|

2 |

Te-Cu |

0.2-0.35% |

0.03-0.05% |

- |

leka-lekanya |

|

3 |

T-P-Cu |

0.4-0.70% |

- |

0.004-0.012% |

leka-lekanya |

|

4 |

Thatafala |

H04, H02, O60 |

|||

| Matla a tšepe |

265 Mpa Min |

||||

| Ho kopanya |

8% Min |

||||

| Tsamaiso ea Motlakase |

90% IACS Min |

||||

| Tekanyo ea Machinability |

90 Min [e ipapisitse le HPb 63-3 (C36000)] |

||||

|

5 |

Boholo | Lahlela D90 mm × L (0.25-5) m, Extruded D (5-40) mm × L (0.25-5) m | |||

|

6 |

E tloaelehileng |

ASTM-C14500 / GB-QTe0.5 / JIS-C1450 / molumo o moholo-CuTeP / BS-C109 |

|||

|

7 |

Ho paka |

Boemong ba plywood |

|||

Malebela a ho reka

- Mohlala o fumaneha ha o kopa

- Tlhahiso ea polokeho ea thepa ka Courier / Air / Sea

- Tsamaiso ea Boleng ba COA / COC

- Ho Sireletsa le ho Paka habonolo

- Ho Paka ho Tloaelehileng ha UN ho fumaneha ha o kopa

- Tlhahlobo ea boleng bo kenyelletsang XRD / SEM / ICP / GDMS jj

- Kakaretso ea Lipehelo tsa Khoebo CPT / FOB / CFR / CIP Ka Incoterms 2010

- Lipehelo tsa Tefo e Tenyetsehang T / TD / PL / C E Amohelehang

- Litšebeletso tse Felletseng tsa Kamora ho Rekisa

- ISO9001: 2015 Certified & Rohs / REACH Regulations Approval

- Litumellano tse sa senoleheng

- Leano le sa Tsamaisaneng la Liminerale

- Tlhahlobo ea Kamehla ea Tsamaiso ea Tikoloho

- Phethahatso ea Boikarabello ba Sechaba

lihlahisoa tse amanang

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu