- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, Chaena.

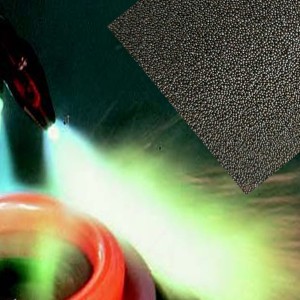

Powder e entsoeng ka samente ea Carbide Hardsurfacing

Tlhaloso

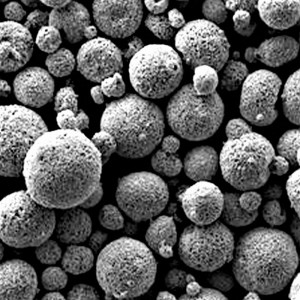

Powder e entsoeng ka samente e entsoeng ka Carbide, ho kenyeletsoa Tungsten Carbide e thehiloeng kapa Chromium Carbide e thehiloeng Thermal Spraying Powder (TSP), e chitja kapa e batla e le chitja e phofshoana e lefifi e nang le phallo e ntle, e sebetsoa ka agglomerated le sintered (A+S) kapa sintered le e sithabetseng (S + C), likarolo ho Lintho tse ikhethang tse kang ho hanyetsa ho hoholo ho hoholo, ho hanyetsa kutu le ho hanyetsa mocheso o phahameng, mocheso o phahameng oa ho sebetsa bakeng sa tungsten carbide e thehiloeng ke hoo e ka bang 500 ° C, chromium carbide e thehiloeng ho 700 ° C-870 ° C.Cemented Carbide Hard-surfacing Powder kapa Tungsten Carbide Hard-surfacing Powder kapa Thermal Spraying Powder e loketse mefuta e fapaneng ea ho fafatsa le plasma spraying welding joalo-joalo merafong, peterole, indasteri ea tšepe, mechini ea temo, tšepe le indasteri ea kaho.

Phano

Cemented Carbide Hard-surfacing Powder at Western Minmetals (SC) Corporation e ka tsamaisoa ka Tungsten Carbide e thehiloeng joalo ka WC-12Co, WC-17Co, WC-10Co4Cr, WC-10Ni, WC-12Ni, WC-17Ni, WC-15NiCr joalo-joalo. le Chromium Carbide e thehiloeng joalo ka Cr3C2-20NiCr, Cr3C2-25NiCr joalo-joalo ka boholo ba 10-30um, 10-45um, 20-59um phofo joalo-joalo, sephutheloana sa 25kg ka mokotleng oa polasetiki o nang le moqomo oa tšepe kantle.

Lintlha

Li-tag

Tlhaloso ea Setsebi

Powder e entsoeng ka samente e entsoeng ka Carbidekapa Thermal Spraying Powder at Western Minmetals (SC) Corporation e ka tsamaisoa ka Tungsten Carbide e thehiloeng joalo ka WC-12Co, WC-17Co, WC-10Co4Cr, WC-10Ni, WC-12Ni, WC-17Ni, WC-15NiCr joalo-joalo le Chromium. Carbide e thehiloeng joalo ka Cr3C2-20NiCr, Cr3C2-25NiCr joalo-joalo ka boholo ba 10-30um, 10-45um, 20-59um phofo joalo-joalo, sephutheloana sa 25kg ka mokotleng oa polasetiki o nang le moqomo oa tšepe kantle.

Thermal Spray Powder Semented Carbide Powder e thata-thata

| Che. | Ntho | Tlhaloso e Tloaelehileng | ||||||

| 1 | Kereiti | TC % | Co % | Cr % | Ke % | Fe % | O % | |

| 2 | Tlhaloso: TSP42 | WC-12Co | 5.2-5.6 | 11.5-12,5 | - | - | ≤1.0 | ≤0.5 |

| Tlhaloso: TSP42D | WC-12Co | 5.2-5.6 | 11.5-12,5 | - | - | ≤0.15 | ≤0.5 | |

| Tlhaloso: TSP43 | WC-17Co | 4.7-5.2 | 16.5-17.5 | - | - | ≤1.0 | ≤0.5 | |

| Tlhaloso: TSP43D | WC-17Co | 4.7-5.2 | 16.5-17.5 | - | - | ≤0.15 | ≤0.5 | |

| Tlhaloso: TSP45 | WC-10Co4Cr | 5.2-5.6 | 9.1-10.1 | 3.0-4.5 | - | ≤1.0 | ≤0.5 | |

| Tlhaloso: TSP45D | WC-10Co4Cr | 5.2-5.6 | 9.1-10.1 | 3.0-4.5 | - | ≤0.15 | ≤0.5 | |

| Tlhaloso: TSP46D | WC-9Co5Cr1Ni | 5.1-5.8 | 8.5-9.5 | 4.5-5.5 | 0.8-1.2 | ≤0.3 | ≤0.5 | |

| Tlhaloso: TSP47D | WC-10Ni | 5.3-5.8 | - | - | 9.0-11.0 | ≤0.2 | ≤0.5 | |

| Tlhaloso: TSP48D | WC-20Cr3C2-7Nna | 5.8-6.4 | - | 20-23 | 6.0-8.0 | ≤0.5 | ≤0.5 | |

| Tlhaloso: TSP49D | Cr3C2-37WC-18NiCoCr | 7.8-8.4 | 3.0-4.0 | 39.5-42,5 | 10.5-12,5 | ≤0.5 | ≤0.5 | |

| Tlhaloso: TSP51D | Cr3C2-20NiCr | 9.7-10.7 | - | Ho leka-lekanya | 15.0-17.0 | ≤0.15 | ≤0.5 | |

| Tlhaloso: TSP52D | Cr3C2-25NiCr | 9.1-10.1 | - | Ho leka-lekanya | 19.0-21.0 | ≤0.15 | ≤0.5 | |

| Tlhaloso: TSP91D | WC-12Ni | 5.2-5.6 | - | - | 11.5-12,5 | ≤0.2 | ≤0.5 | |

| Tlhaloso: TSP92D | WC-17Ni | 5.0-5.3 | - | - | 16.5-17.5 | ≤0.2 | ≤0.5 | |

| Tlhaloso: TSP93D | WC-15NiCr | 5.0-5.4 | - | 2.5-3.5 | 11.5-12,5 | ≤0.5 | ≤0.5 | |

| 3 | Botenya | WC E Thehiloe | Boima bo hlakileng ≥4.0 g/cm3 | |||||

| Cr3C2E thehiloe | Tšebeliso e hlakileng ea TSP49D ≥2.5g/cm3, TSP51D TSP52D ≥2.0 g/cm3 | |||||||

| 4 | Boholo | μm | 53-20 | 45-20 | 45-15 | 45-11 | 38-10 | 30-10 |

| Litefiso tsa Phallo / 50g | WC E Thehiloe | ≤18 | ≤18 | ≤18 | ≤18 | ≤18 | ≤30 | |

| Cr3C2E thehiloe | - | - | - | - | - | - | ||

| 5 | Grain Morphology | TSPXXD e chitja kapa e batla e le chitja ka Agglomerated and Sintered | ||||||

| 6 | Ho paka | 25kg kapa 50kgs ka mokotleng oa polasetiki o nang le moqomo oa tšepe kantle | ||||||

Malebela a Theko

- Sample e Fumaneha ka Kopo

- Phano ea Tšireletseho ea Thepa Ka Courier/Air/Sea

- Tsamaiso ea Boleng ea COA / COC

- Sireletsehile & Habonolo Packing

- UN Standard Packing e Fumaneha ka Kopo

- ISO9001: 2015 e netefalitsoeng

- Melao ea CPT/CIP/FOB/CFR Ka Incoterms 2010

- Melao ea Tefo e Fetohang T/TD/PL/C E A amoheleha

- Litšebeletso tse Felletseng ka mor'a ho rekisoa

- Tlhahlobo ea Boleng ka Setsi sa Sate-of-the-art

- Kamohelo ea Melao ea Rohs / REACH

- Litumellano tse sa senoleheng NDA

- Leano la Liminerale le sa Khohlano

- Tlhahlobo ea Kamehla ea Tsamaiso ea Tikoloho

- Phethahatso ea Boikarabello ba Sechaba

Thermal Spray Powder

Phofo e thata

lihlahisoa tse amanang

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu