- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, Chaena.

Silicon Carbide SiC

Tlhaloso

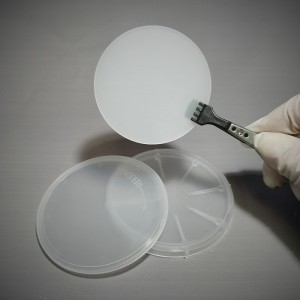

Silicon Carbide Wafer SiC, e thata ka ho fetisisa, e entsoeng ka maiketsetso e entsoeng ka silicon le carbon ka mokhoa oa MOCVD, le lipontšo.lekhalo la eona le ikhethang la sehlopha se pharaletseng le litšobotsi tse ling tse ntle tsa katoloso e tlase ea mocheso, mocheso o phahameng oa ts'ebetso, ho felloa ke mocheso o motle, tahlehelo e tlase ea ho switjha le ho tsamaisa, ho sebetsa hantle haholo, ho sebetsa ka mocheso o phahameng le matla a matla a ho senyeha ha masimo a motlakase, hammoho le maqhubu a mangata. boemo.Silicon Carbide SiC at Western Minmetals (SC) Corporation e ka fanoa ka boholo ba 2 ″ 3' 4" le 6 ″ (50mm, 75mm, 100mm, 150mm) bophara, ka mofuta oa n, semi-insulating kapa dummy wafer bakeng sa indasteri. le ts'ebeliso ea laboratori.Tlhaloso efe kapa efe e hlophisitsoeng ke ea tharollo e phethahetseng ho bareki ba rona lefatšeng ka bophara.

Lisebelisoa

Boleng bo phahameng ba 4H/6H Silicon Carbide SiC bafer e nepahetse bakeng sa ho etsa lisebelisoa tse ngata tsa elektroniki tse potlakileng, tse phahameng haholo le tse nang le matla a phahameng joalo ka Schottky diode & SBD, MOSFETs & JFETs, joalo-joalo. hape ke thepa e lakatsehang lipatlisisong le nts'etsopele ea li-insulated-gate bipolar transistors le thyristors.E le sesebelisoa se hlahelletseng sa semiconducting sa moloko o mocha, Silicon Carbide SiC wafer e boetse e sebetsa e le sesebelisoa se sebetsang hantle sa mocheso likarolong tse matla tsa LED, kapa e le setsi se tsitsitseng le se tsebahalang bakeng sa ho holisa GaN layer molemong oa boithuto ba mahlale ba nakong e tlang.

Lintlha

Li-tag

Tlhaloso ea Setsebi

Silicon Carbide SiCho Western Minmetals (SC) Corporation e ka fanoa ka boholo ba 2″ 3' 4“ le 6 ″ (50mm, 75mm, 100mm, 150mm) bophara, ka mofuta oa n, semi-insulating kapa dummy wafer bakeng sa ts'ebeliso ea indasteri le laboratori. .Tlhahiso efe kapa efe e hlophisitsoeng ke ea tharollo e phethahetseng ho bareki ba rona lefatšeng ka bophara.

| Linear Foromo | SiC |

| Boima ba Molek'hule | 40.1 |

| Sebopeho sa kristale | Wurzite |

| Ponahalo | Tiileng |

| Melting Point | 3103±40K |

| Ntlha e belang | N/A |

| Boima ba 300K | 3.21 g/cm3 |

| Lekhalo la Matla | (3.00-3.23) eV |

| Ho hanyetsa ka hare | >1E5 Ω-cm |

| Nomoro ea CAS | 409-21-2 |

| Nomoro ea EC | 206-991-8 |

| Che. | Lintho | Tlhaloso e Tloaelehileng | |||

| 1 | SiC boholo | 2" | 3" | 4" | 6" |

| 2 | Diameter mm | 50.8 0.38 | 76.2 0.38 | 100 0.5 | 150 0.5 |

| 3 | Mokhoa oa Kholo | MOCVD | MOCVD | MOCVD | MOCVD |

| 4 | Mofuta oa conductivity | 4H-N, 6H-N, 4H-SI, 6H-SI | |||

| 5 | Ho hanyetsa Ω-cm | 0.015-0.028;0.02-0.1;>1E5 | |||

| 6 | Boitloaelo | 0°±0.5°;4.0° ho ea ho <1120> | |||

| 7 | Botenya μm | 330±25 | 330±25 | (350-500)±25 | (350-500)±25 |

| 8 | Sebaka sa Mathomo a Flat | <1-100>±5° | <1-100>±5° | <1-100>±5° | <1-100>±5° |

| 9 | Bolelele ba Pele ba Botho ba mm | 16±1.7 | 22.2±3.2 | 32.5±2 | 47.5±2.5 |

| 10 | Sebaka sa Bobeli sa Flat | Silicon e shebane holimo: 90 °, ho ea ka nako ea oache ho tloha sephara se seholo ± 5.0 ° | |||

| 11 | Bolelele ba Bokhabane ba Bobeli mm | 8±1.7 | 11.2±1.5 | 18±2 | 22±2.5 |

| 12 | TTV μm max | 15 | 15 | 15 | 15 |

| 13 | Inamela μm max | 40 | 40 | 40 | 40 |

| 14 | Warp μm max | 60 | 60 | 60 | 60 |

| 15 | Kenyelletso ea moeli mm max | 1 | 2 | 3 | 3 |

| 16 | Micropipe Density cm-2 | <5, indasteri;<15, lab;<50, bohlanya | |||

| 17 | Dislocation cm-2 | <3000, indasteri;<20000, lab;<500000, dummy | |||

| 18 | Surface Roughness nm max | 1(E bentšitsoeng), 0.5 (CMP) | |||

| 19 | Mapetso | Ha ho letho, bakeng sa boemo ba indasteri | |||

| 20 | Lipoleiti tsa Hexagonal | Ha ho letho, bakeng sa boemo ba indasteri | |||

| 21 | Mengwapo | ≤3mm, bolelele bohle bo ka tlase ho bophara ba substrate | |||

| 22 | Li-Chips tsa Edge | Ha ho letho, bakeng sa boemo ba indasteri | |||

| 23 | Ho paka | Sets'oants'o se le seng sa wafer se tiisitsoeng ka mokotleng oa aluminium composite. | |||

Silicon Carbide SiC 4H/6Hsephaphatha sa boleng bo holimo se loketse ho etsoa ha lisebelisoa tse ngata tsa elektroniki tse potlakileng, tse phahameng haholo le tse nang le matla a phahameng joalo ka Schottky diode & SBD, MOSFETs & JFETs, joalo-joalo. Hape ke ntho e lakatsehang lipatlisiso le nts'etsopele ea li-insulated-gate bipolar transistors le thyristors.E le sesebelisoa se hlahelletseng sa semiconducting sa moloko o mocha, Silicon Carbide SiC wafer e boetse e sebetsa e le sesebelisoa se sebetsang hantle sa mocheso likarolong tse matla tsa LED, kapa e le setsi se tsitsitseng le se tsebahalang bakeng sa ho holisa GaN layer molemong oa boithuto ba mahlale ba nakong e tlang.

Malebela a Theko

- Sample e Fumaneha ka Kopo

- Phano ea Tšireletseho ea Thepa Ka Courier/Air/Sea

- Tsamaiso ea Boleng ea COA / COC

- Sireletsehile & Habonolo Packing

- UN Standard Packing e Fumaneha ka Kopo

- ISO9001: 2015 e netefalitsoeng

- Melao ea CPT/CIP/FOB/CFR Ka Incoterms 2010

- Melao ea Tefo e Fetohang T/TD/PL/C E A amoheleha

- Litšebeletso tse Felletseng ka mor'a ho rekisoa

- Tlhahlobo ea Boleng ka Setsi sa Sate-of-the-art

- Kamohelo ea Melao ea Rohs / REACH

- Litumellano tse sa senoleheng NDA

- Leano la Liminerale le sa Khohlano

- Tlhahlobo ea Kamehla ea Tsamaiso ea Tikoloho

- Phethahatso ea Boikarabello ba Sechaba

Silicon Carbide SiC

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu